Non-welded Piping Solutions

for Marine, Offshore and Land-based industries

A World Leader

in Non-Welded Piping Solutions

GS-Hydro is the original provider of non-welded piping systems for industries with high demand on quality. The leak-free piping solutions are preferred especially in the offshore, marine and land-based industries such as pulp and paper or steel industries. The reliability and numerous advantages of GS systems can be utilized in numerous high and low pressure applications with media such as water, oil, air, gas and mud.

Founded

1974

years of experience

45+

Employees

400+

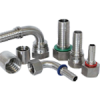

Product range

GS-HYDRO Services

GS-Hydro is able to offer its customers professional services ranging from state-of-the-art engineering to all needed services on-site. GS-Hydro can offer quality piping solutions as most of the component are prefabricated using automated machines. In addition, all of GS-Hydro’s technology innovations have relevant type approvals and certificates which can be included in the documentation package delivered to the customer.